Indexing Rotary Table for Aerospace Manufacturing

No Comments - Leave a Comment

An integrator building a system for Boeing Aerospace Company had a strict requirement for a “Zero Backlash” rotation system for positioning of reverse thruster part as it was being assembled. The reverse thruster and carriage had a total load of 4000 lbs with a payload of a physical size of 140”x 80” x 60” and a 5:1 safety factor. The indexing rotary table positioning system had to be manufactured to allow for slight misalignment and equipped with a safety locking device to prevent positioning system from moving during maintenance or assembling parts.

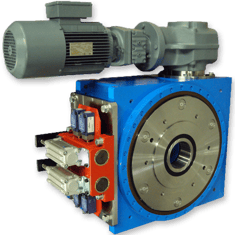

The RT series 400-Flex trunnion is equipped with a programmable barrel cam which fit the end customer’s specifications. The barrel cam/cam follower mechanism opewqsrates in a preload condition allowing for a true “zero backlash” operations. Unlike gear reducers, the barrel cam must have zero backlash to operate correctly. The barrel cam solution is the only true “Zero Backlash” rotation mechanism on the market today. Our case hardened barrel cams (5 mm depth) and needleless cylindrical cam followers allows for maximum torque to be generated. The custom floating bearing assembling on the tail end, opposite of the RT400-Flex unit allowed for slight misalignment. The tail end bearing assembly was able to float in and out to accommodate any structural size differences that may occur from expansion and contraction. We equipped the RT400-Flex indexing rotary table with a safety lock out device and custom output flange to give Boeing plenty of option to engage the safety lock-out device at multiple angular positions.

Comments

No Comments - Leave a Comment

Translate

Translate