Benefits of Manufacturing with a Parallel Rotary Indexer

No Comments - Leave a Comment

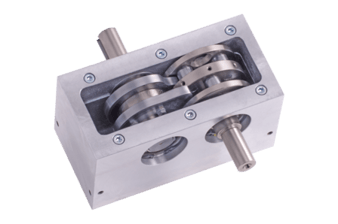

Sometimes an application calls for an indexer with unique qualities: specific dimensions, continuous operation capabilities, short indexes and long mechanical dwells. Motion Index Drives’ Parallel Rotary Indexer bring Motion’s robust construction process and materials to the versatile parallel shaft design. Low friction internal components and the added bonus of less

internal inertia thanks to the unit’s disk cam configuration make these Parallel Drives one of the most energy efficient indexers available.

Benefits of manufacturing with a Parallel Rotary Indexer are they make great solutions for driving conveyors, acting as torque arms and performing tasks that require flipping or rotating tooling. In addition, Motion Index Drives can construct custom drives for continuous operation in an environment where a motor off mode of operation is not an option.

Parallel Index Drives are high-precision, long-lasting and maintenance-free work horses. Continuous operation capabilities and easy synchronization of other mechanical devices make Motion Parallel Indexers a good fit for any application.

XP Series indexers provide the most compact indexing drive option available. The parallel shaft configuration is one sought out for several applications.

The product line offers high speeds and what may be the most practical shaft design (including the potential for output shafts on both sides of the unit).

Large projects for Motion Index Drives’ parallel indexers have included acting as a conveyor drive in an existing battery manufacturing system and driving lever arms in a fast-paced packaging process.

The speed of parallel indexers is another primary reason to incorporate them into automation process. With the potential of reaching over 600 cycles per minute and relatively long dwell phases, these indexers are selected for many applications requiring continuous operation.

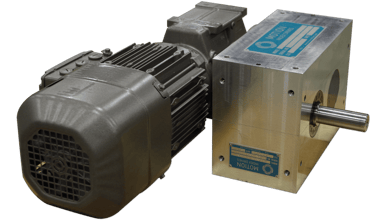

Parallel Indexers often don’t have motors mounted directly to their housing. Designers may select a parallel for its unique dimensions and locate a drive unit elsewhere. The indexer can then be driven via a belt or indirect means, and the potential for a double-sided input shaft can allow designers to run other devices continuously from the indexer’s input.

Like the TT Series, the TP Series offers alternative sizes and standard aluminum housing.

Comments

No Comments - Leave a Comment

Translate

Translate