Rotary Indexing Tables used for X-Ray Imaging

No Comments - Leave a Comment

Experienced process automation engineers have used rotary indexing tables at one time or another to move product from one station to another in a very precise manner. Precision positioning in many cases is extremely important on products that require operations that have tolerances that our within thousandths of inches. A highly accurate rotary indexing table is ideal for these applications.

Another area where precision linear and rotary indexing is required that most automation engineers do not realize is x-ray imaging. This includes x-ray imaging of ocear cargo, air cargo, parcels etc. To get very clear images the precise rotary index table is a key component to achieve clear images to be able to detect dangerous materials or contraband hidden in packages.

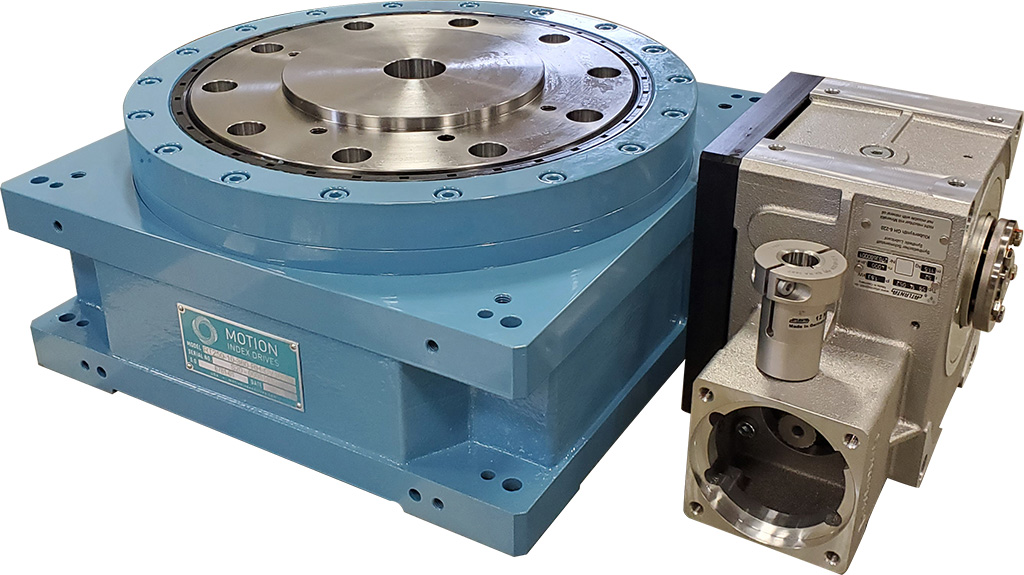

Compactness of a robust rotary index table is also important to be able to fit into a scanning machine. At Motion Index Drives we take a standard programmable indexer and reinforce the bearing assembly to accommodate tilting moments and heavy cargo loads that will be scanned. We equip these standard units with very high precision high torque gear reducers to achieve better than 5 arc seconds of accuracy. With our accuracy and “ZERO BACKLASH COMPONENTS” our customers are able to create a very clear image when performing a scan.

Our programmable rotary index tables can be manufactured to accept a variety of servo motors and auxiliary axis robot motors. Motion Index Drives engineers will size each application to let the customer know what motor size should be used and what movement profile is ideal to optimize performance.

Learn more about our Indexing Rotary Tables from our Guide.

Comments

No Comments - Leave a Comment

Translate

Translate