Sizing your Rotary Index Table

No Comments - Leave a Comment

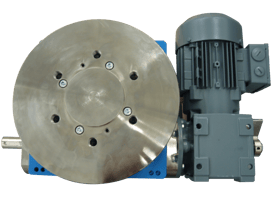

Sizing a rotary index table can become a very complicated task, but here are three basic items to consider in estimating a size:

1. Swing Diameter: The relationship of the swing diameter to the cam follower pitch diameter is kept to 8:1 or less, never to exceed 10:1. For example, an application of 2000mm can be sized by dividing 2000 by 8 (2000/8=250), sizing the table at an RT250; 1800mm/8=225 (also RT250); 1600/8=200 (RT200). Maximum recommended swing diameter is listed in the on the first

page for each model. View our Catalog.

2. Load Inertia: This is potentially the most difficult to determine. To estimate the worst case, multiply (total load) by (radius^2 by (1,500kp*1.5m2=3375kg*m2; if we were sizing an RT400-4 stop, this would require an index time o f 3.82s [see load table on 28 of product catalog]). If possible, substitute the center of gravity radius for application radius ([total load]*[center of gravity radius]^2). Also, Motion’s internal TCC calculator can help estimate inertia.

3. Indexing Time: The more index time available, the greater inertia an index table can handle. If an application can be slower, do so, as it will allow for the use of a smaller indexer and be more cost effective (or reduce stress placed on the table). In exceptional circumstances, a fourth criteria must be considered:

4. Load Weight: If the index time is not a factor, total load weight must be checked to not exceed bearing capabilities. Bearing capabilities can be found in the catalog under each model.

* NOTE: Trunnions consider the above, but the out of balance (static) torque is a new item that must be considered. Static torque is generally the deciding factor in sizing a trunnion. Flexible index drives are stronger than their fixed counterparts, as they always have a minimum of two cam followers engaged in preload (new TMF indexers will have up to five contacting the cam at any time). To size a flexible rotary index table unit, assume the same size as the fixed for preliminary estimates until final loading can be calculated by engineering.

For parallel and right angle (globoidal) rotary indexers, output torque tends to be the most critical item to determine. Please ask customers for required torque if sizing a parallel, along with the cycle rate. These can help determine a unit quickly.

View more information in our Guide to Rotary Index Tables.

Comments

No Comments - Leave a Comment

Translate

Translate