Types of Rotary Welding Positioners

No Comments - Leave a Comment

TYPES OF ROTARY WELDING POSITIONERS

Rotary welding positioners can be devices that are a must-have for a factory or company looking to increase productivity when welding a product. These welding positioners act similarly to vertically mounted rotary indexing tables, with a 360 degree rotational range while holding a part or product to be modified or assembled. Most rotary welding positioners hold a weldment in a chuck, rotating the weldment in a plane perpendicular to the floor. This positioning and rotation allows the weldment to be welded very easily either by a human operator or an automated welder. It is a beneficial tool in either scenario, as a human will be able to weld a part without positioning themselves around the part, increasing comfort and decreasing fatigue, while automated tools that make modifications to the weldment will all be able to remain stationary and increase welding speed, all with a smaller physical footprint.

There are a multitude of different types of rotary welding positioners, as they come in all shapes and sizes depending on the application they are to be used in. The most basic type of rotary welding positioners is a rotary indexer.

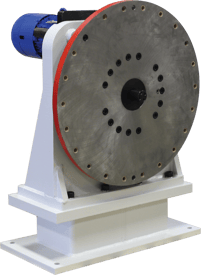

Rotary Indexer Weld Positioners

Rotary indexers are a standard rotary welding positioner, and often have the fewest moving parts and features. They are capable of operating in flat or horizontal positioning, with most rotary indexers capable of switching between the two positions. Rotary indexers are used in many precise welding applications, and have variable speed controls, including reversing rotation directions. They are often used for welding round objects, although any weldment that can benefit from being rotated to present the next weld to the welder can be more efficiently welded. If used on their own, they are most effective when working with parts with shorter length, or shorter overhang. When working with longer parts, standard rotary indexers need assistance in supporting the parts due to leverage from the overhang, especially when the part is long and extends far from the base of the indexer.

Welding Positioner Supporting Methods

There are several tools that work in tandem with rotary indexers, specifically when it comes to supporting larger or longer parts.

Rollers are a common tool used when extra support is needed for large parts, and can either be powered or idler type. Powered rollers can roll a part to be welded on their own, however, they may not have the precision of positioning that a rotary indexer has to accurately position a part for an automated welding system. For this reason, idler rollers are far more commonly used with rotary weld positioners. They are best suited to supporting cylindrical weldments, especially pipes, as these are the weldments that would roll the most easily.

For the biggest, heaviest parts, and parts that won’t roll as easily, tailstocks are often employed to assist rotary indexers. Tailstocks can support weldments of almost any shape, with a chuck similar to the rotary indexer’s that grips onto the opposite end of the weldments. They allow for the maximum flexibility when lifting and rotating the largest and heaviest pieces, and are often synchronized with the headstock in terms of height adjustment, so that the weldment stays level when it is being rotated.

View more information on Motion Index Drives HeadStock TailStock Trunnion Sets.

Multi-Axis Indexering Weld Positioners

For the most degrees of freedom available and therefore the best access to every area of the weldment, multi-axis indexers are the go-to tool for many companies looking to improve their productivity when welding. The quality of welds is often also improved when using multi-axis indexers, as the increased access to every area of the part allows the welder or automated welder to move the minimal amount, even with non-symmetrical shaped weldments.

Multi-axis indexers have many different variants, including indexers with one mounting position for weldments, and positions for several weldments. One of the most common kinds is a double trunnion setup, with a pair of headstocks and tailstocks arranged parallel to one another. This configuration is located on a large turntable that allows the entire configuration to rotate 180 degrees. This is useful when trying to increase productivity, as on one trunnion, a part can be loaded and unloaded while a part is being welded on the other trunnion. When this operation is complete, the positioner rotates 180 degrees and the process repeats itself. This allows for minimal time that the welder or loader spends waiting on the other, decreasing downtime and increasing production levels.

View more information on Motion Index Drives Multi-Axis Weld Positioners.

It is important that a company or manufacturing facility does some research on which welding positioner would best suit their needs, including reaching out to the manufacturers of welding positioners. They have proven time and again to be a valuable tool in welding applications, making welding processes easier and faster than ever before. Whatever type of positioner is selected, the welding speed, efficiency and quality of a facility is likely to noticeably increase, and profit margins will increase as a result.

Want to learn more about Weld Positioners? Go to our guide here!

Comments

No Comments - Leave a Comment

Translate

Translate